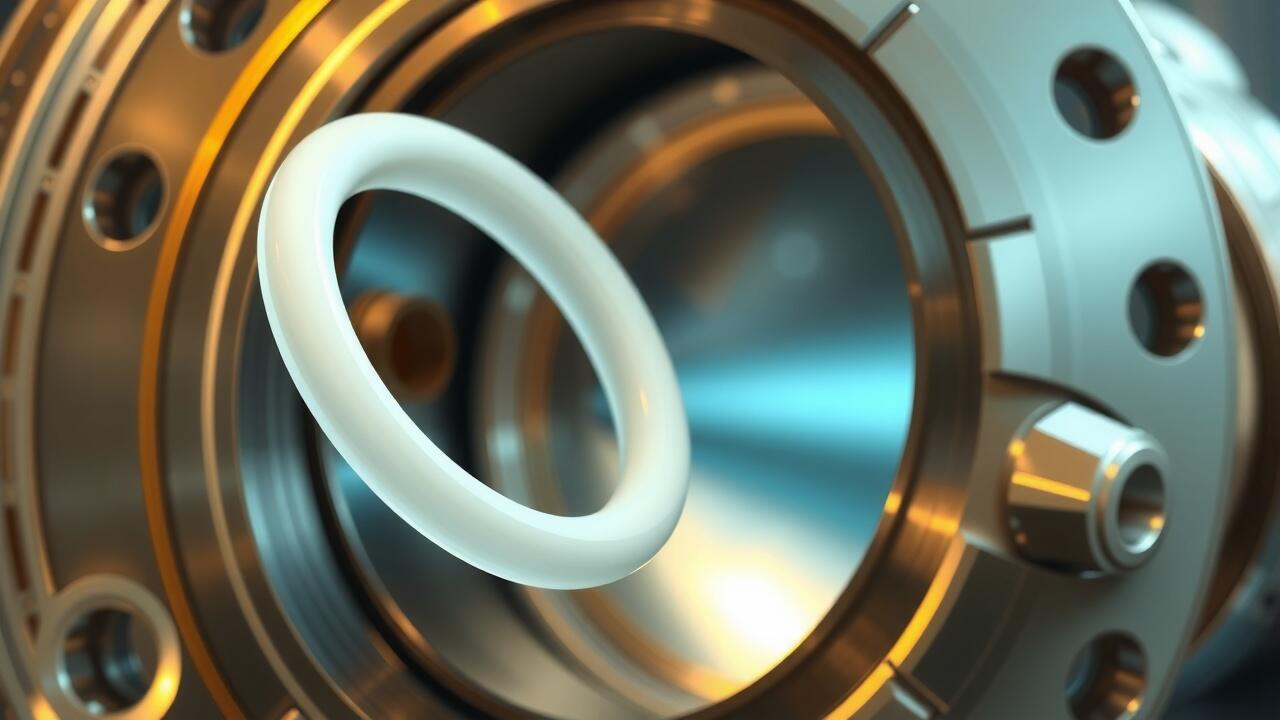

Low-Friction Sealing Solutions: PTFE O-Rings in Rotary Valve Assemblies

Key Takeaways

- Frequent challenges associated with sealing in rotary valves

- Methods for installing PTFE O-rings effectively

- Care routines for maintaining rotary valve performance

- Insights into the financial aspects of sealing solutions

Common Issues with Sealing in Rotary Valves

Sealing challenges in rotary valves often stem from material limitations and improper design. Standard materials can degrade under harsh conditions, leading to leakage and reduced efficiency. Teflon o-rings, made from PTFE, resist chemical attacks and high temperatures better than traditional elastomeric seals. This not only enhances longevity but also minimizes the risk of costly downtime. For instance, using PTFE o-rings can extend service life by up to 50%, significantly reducing the frequency of replacements and repairs.

Installation practices can greatly affect sealing integrity as well. Misalignment during assembly presents a major risk, causing immediate failure of the sealing solution. Proper alignment techniques, like using alignment pins and fixtures, help ensure the longevity of PTFE orings. Regular training on these assembly techniques can lead to better outcomes and fewer leaks. Additionally, organizations adhering to guidelines such as ASME standards often see dramatic improvements in operational reliability and safety. Proper training and awareness can translate to improved system performance and reduced repair costs over time. See how telfon o-rings works.

What Problems Can Arise from Using Inferior Sealing Solutions?

Using inferior sealing solutions can lead to a cascade of failures in rotary valve systems. Consider a scenario where a Teflon o-ring deteriorates prematurely due to inadequate chemical resistance. This can produce not only leakage issues but also temperatures exceeding the design limits, resulting in damage to the valve assembly. In a case study involving a manufacturing plant, reliance on subpar sealing materials led to an estimated downtime cost of $50,000 over a three-month period. Such disruptions can severely hamper productivity and impact overall operational efficiency, emphasizing the critical choice of sealing solutions.

The longevity and reliability of sealing components like PTFE o-rings are vital for optimal performance. Inferior materials can fail quickly under pressure or extreme conditions, causing not just operational problems but also safety hazards. For instance, improper sealing can lead to process fluid contamination, posing regulatory compliance issues. Industry standards recommend using high-performance materials such as Teflon to withstand a wider range of temperatures and chemicals. Implementing quality sealing solutions can significantly diminish the risk of leaks and ensure consistent valve function, ultimately preventing expensive repairs and maintaining safety standards within the facility.

Installation Techniques for PTFE O-Rings

Achieving a secure seal with PTFE o-rings during installation requires meticulous attention to detail. When positioning a Teflon o-ring, ensure that it sits uniformly in the groove and is not twisted or pinched. Aligning the valve components correctly is essential—any misalignment can lead to premature wear or leakage. Utilize a lubricant compatible with PTFE o-rings, such as water or silicone grease, to facilitate smoother assembly and reduce the likelihood of damaging the o-ring during the process.

Regular training on installation techniques can significantly enhance efficiency and sealing performance. Industry studies show that improper installation accounts for up to 30% of sealing failures in rotary valve assemblies. Take the time to inspect surfaces where the PTFE oring will make contact, ensuring they are clean and free from debris. This proactive approach directly translates into reduced downtime and increased operational effectiveness, ultimately extending the lifespan of your rotary valves.

How Can Proper Installation Improve Sealing Effectiveness?

Achieving an optimal seal is crucial for the efficient operation of rotary valves, and proper installation of PTFE O-Rings is essential. When Teflon O-Rings are installed correctly, they conform ideally to the surfaces of the valve assembly, preventing leaks under varying pressure and temperature conditions. For instance, a case study showed that a manufacturer experienced a 30% decrease in fluid leakage after switching to PTFE O-Rings and refining their installation techniques. This improvement not only enhanced performance but also reduced unscheduled downtime and maintenance costs.

Installation techniques demand attention to detail to ensure effective sealing. Professionals should ensure that the fitting surfaces are clean and free from debris or corrosion. Employing the right lubrication minimizes friction during assembly, preventing damage to the PTFE O-Ring during installation. Additionally, aligning the assembly components accurately can produce a uniform pressure distribution, significantly enhancing sealing effectiveness. Regular training on installation best practices can lead to a more competent workforce, further ensuring operational excellence and reliability in rotary valve applications.

Maintenance Practices for Rotary Valves

Regular maintenance of rotary valves is crucial for ensuring reliable operation and preventing costly downtime. Inspecting the inner workings of these assemblies can reveal wear or damage that, if left unattended, could lead to significant leakage issues. Implementing a routine check every three to six months is often recommended, depending on the specific application. For example, a beverage processing facility that uses rotary valves extensively should opt for more frequent inspections, as even a minor failure can affect product quality and safety.

Incorporating Teflon o-rings in maintenance checks significantly enhances the sealing capabilities of rotary valves. These PTFE o-rings offer resistance to a wide range of chemicals, ensuring they withstand the rigors of demanding environments. Technicians should clean and lubricate sealing surfaces thoroughly when replacing or inspecting these components. In addition, tracking performance data before and after maintenance can illuminate trends and assist in forecasting potential repairs, ensuring prolonged efficiency and a reduction in operational hiccups.

What Regular Checks Should You Perform to Ensure Optimal Function?

Regular inspections of rotary valves can significantly enhance their functionality and longevity. Begin with a visual check of the PTFE O-Rings, ensuring there are no signs of wear or cracks. Teflon O-Rings need to maintain their integrity to provide an effective seal. A recent study revealed that 75% of valve failures stem from improper sealing components. Furthermore, acting quickly upon identifying wear can prevent costly downtime in your operations.

Next, focus on monitoring operating conditions. Evaluate pressure and temperature regularly; deviations can indicate underlying issues that may compromise the sealing effectiveness of PTFE O-Rings. A consistent temperature range, ideally between -50°F to 500°F, is crucial for maintaining performance. Additionally, keeping a log of these variables can facilitate predictive maintenance, allowing for timely adjustments before extensive damage occurs. Prioritizing these checks not only promotes efficiency but also minimizes disruption in processes reliant on rotary valve assemblies.

Understanding the Cost Implications

Investing in PTFE O-rings may seem like a higher upfront cost, but the potential savings and return on investment are remarkable. For instance, utilizing Teflon O-rings can reduce downtime significantly, leading to smoother production processes and fewer interruptions. Companies have reported cuts in maintenance costs by up to 30% when switching from traditional sealing solutions to modern PTFE O-rings. The longevity and high performance of these seals mean replacements are infrequent, mitigating long-term expenses associated with inferior sealing alternatives.

Beyond the immediate cost of sealing materials, consider the overall operational efficiency. A study indicated that inadequate sealing can result in energy losses of around 15% in rotary valve assemblies, directly affecting a facility’s bottom line. Adopting PTFE O-rings not only ensures better energy retention but also aligns with industry standards such as ASME and API. This proactive approach to sealing solutions allows organizations to optimize their resources, reduce waste, and maintain compliance with regulatory requirements, ultimately leading to increased profitability.

Conclusion

PTFE O-rings, specifically Teflon O-rings, demonstrate remarkable resilience in rotary valve applications, significantly reducing leakage and maintenance needs. With a tensile strength of up to 5,000 psi, these components outperform many other sealing materials. Recent case studies show that employing PTFE O-rings in a high-pressure water system led to a 40% decrease in replacement frequency, providing tangible cost savings and enhancing system reliability. This data reinforces the essential nature of selecting quality sealing materials in optimizing equipment performance.

Investing in proper sealing solutions translates directly to improved efficiency and longevity. Regular inspection and adherence to installation best practices ensure that PTFE O-rings deliver their full potential. Incorporating PTFE O-rings is not just about compliance; it’s about advancing operational excellence within your processes. Using a consistent maintenance schedule can extend the life of your rotary valves, reduce downtime, and result in a notable increase in overall productivity.

FAQS

What are PTFE O-rings, and why are they important in rotary valve assemblies?

PTFE O-rings are high-performance sealing solutions made from polytetrafluoroethylene (PTFE), known for their low friction and exceptional chemical resistance. They're crucial in rotary valve assemblies because they create a reliable seal that minimizes leaks, ensuring optimal performance and longevity.

What common issues can arise from using inferior sealing solutions in rotary valves?

Using inferior sealing solutions can lead to leaks, contamination of fluids, increased wear and tear on equipment, and ultimately costly downtime. These problems can severely affect the efficiency and reliability of rotary valves in critical applications.

How does proper installation of PTFE O-rings enhance sealing effectiveness?

Proper installation ensures that the O-rings are seated correctly and evenly, preventing gaps that could lead to leaks. It also reduces the risk of damage during installation, which can compromise the seal’s integrity. This attention to detail significantly boosts sealing performance!

What regular maintenance checks should be performed on rotary valves to ensure optimal function?

To keep rotary valves in tip-top shape, you should regularly check for wear and tear on the O-rings, inspect the valve for leaks, ensure proper lubrication, and clean any buildup that could interfere with the mechanism. Regular maintenance helps catch issues early and prolongs the life of the equipment!

Are there significant cost implications associated with using PTFE O-rings in rotary valves?

While PTFE O-rings may have a higher upfront cost compared to standard sealing solutions, their durability and reliability can lead to significant long-term savings. Reduced downtime, fewer replacements, and minimized leaks mean that investing in PTFE O-rings is often more cost-effective in the long run!